Tub çeliku inox me formë të veçantë

Shkalla e çelikut

304: 0Cr18Ni9, 06Cr19Ni10

201: 1cr17mn6ni5n, 1cr13mn9ni1n

304L: 00Cr19Ni10

316L: 022Cr17Ni12Mo2 00Cr17Ni14Mo2

ose si kërkesë e klientit

Standard: ASTM A554 .GB / T 12770 .JIS G3446 .JG / T 3030 .YB / T 5363, kërkesat e klientëve në dispozicion

Madhësia: 6mm12.7,15.9,16,17.15,18,19.1,20,22.2,25.4,26.67,27,28,28.6,29,30,31.8,32,33,4,33.7,34,35,36,38.1 40,41.3,42,

44.5,45,48.26,50.8,54,57,60,60.33,63.5,73,76.2,80,85,88.9,95,100,101,610,108,108,120,114.3,127,133,141,152,159,168,178,219,254,273,323.85,426mm

e trashë: 0,4 mm-8,0 mm

Gjatësia: 6m ose sipas kërkesës së klientit

Tolerancë Diametri i jashtëm: ± 0.2 mm

Trashësia: ± 0,02 mm

Gjatësia: ± 0,5 mm

Procesi: Metoda e tërhequr në të ftohtë, e Pjekur me mbrojtje të azotit, saldim tejzanor,

Forma automatike, e lëmuar, Paketimi.

Mbaron Në skajet e thjeshtë ose të pjerrët ose sipas kërkesave të klientëve

Sipërfaqja: 180 # .220 # .320 # .400 # .600 # .HL.MF 8K.etj

Paketimi i brendshëm Qese plastike

Paketimi i jashtëm Gunny standard i paketuar për secilën pako, rreth 300-500 kg për

pako, ose e personalizuar sipas kërkesave të klientëve

Dekore, ndërtime

Zbatimi Industria e naftës dhe kimike

Industria ushqimore dhe industria farmaceutike

Ndërtimi i anijeve dhe prodhimi i automobilave

Sistemet e transportit ujor

Rezistent, i pandryshkshëm, rezistent ndaj korrozionit, anti-veshur, mirë

Pamja e performancës, vetitë e shkëlqyera mekanike

Certifikimi ISO, SGS, BV.

Lloji i Saldimit ERW (Saldimi i Rezistencës Elektrike)

Detaji i Dorëzimit 15 ~ 25 ditë, varet nga sasia e porosisë së klientëve

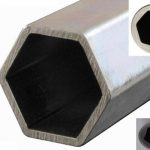

Shaped tubing refers to tubing that is not round (circular) in form. Frequently, applications involve some type of stainless steel support for a product, a path or race for fiberoptics or other smaller components, or a dispensing application. Depending on requirements detailed by the customer, shaped tubing can be made stronger in some directions in a similar manner to the concept of an I-beam. All tubing drawn into shapes has to be formed through custom manufactured dies and subsequently straightened though specially formed tooling for straightening profiled tubing. In some cases, customer requirements result in a modest engineering fee for the design work associated with developing a method to form the tube. Emily Metal supplies shaped tubing in a variety of alloys, most popularly in 304 or 316 stainless steel. However, all alloys that Emily Metal produces can be drawn into shapes provided the shape is capable of being formed.

One factor to consider when sourcing shaped tubing is tolerances placed on non-critical features of the tube. Controlling radii and angles too tightly on an engineering print can increase costs and in some cases render requested product unmanufacturable. Increasingly sharp corners on shaped tubing (at the corners of a square, for example) increase manufacturing complexity. An additional consideration is cutting the product to final length or secondary forming. Because shaped tubing may be difficult to cut accurately and burr free, Emily developed tooling that permits accurate completion of these operations with rapid turnaround. Many of our secondary forming operations are also available on profiled tubing, subject to some operation-specific limitations.

Some of the shapes and profiles produced by Emily, include but are not limited to the following:

Squares

Rectangles

Ovals

Triangles

Stars

Hybrid shapes

Half circles

“I” shape

“T” shape