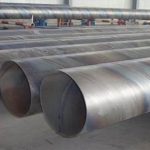

Tub çeliku ERW HFI EFW

ERW: Tub i salduar me rezistencë elektrike

HFI: Tub saldimi me induksion me frekuencë të lartë

EFW: Tub i salduar me bashkim elektrik

Standard: API 5L, API 5CT, ASTM 53, EN10217, DIN 2458. IS 3589, JIS G3452, BS1387

Certifikata: API 5L PSL1 / PSL2, API 5CT

Diametri i daljes: 21.3 mm - 610 mm

Trashësia e murit: 1.8 - 22 mm

Gjatësia: 0.3 - 12m

Shkalla e çelikut: API 5L: GR B, X42, X46, X56, X60, X65, X70

ASTM A53: GR A, GR B, GR C

EN: S275, S275JR, S355JRH, S355J2H

GB: Q195, Q215, Q235, Q345, L175, L210, L245, L320, L360- L555

Sipërfaqja: Veshje epoxy e lidhjes së shkrirjes, Epoxy Tar Tar, 3PE, Veshje Vanish, Veshje bitumi, Veshje e Vajit të Zi sipas kërkesave të klientit

Testi: Analiza e Komponentit Kimik, Karakteristikat Mekanike (Rezistenca e fundit në tërheqje, Forca e Rendimentit, Zgjatja), Karakteristikat Teknike (Prova e Rrafshimit, Prova e Përkuljes, Prova e Goditjes, Prova e Ndikimit), Inspektimi i Madhësisë së Jashtme, Testi Hidrostatik, Prova me rreze X.

Certifikata e Testit të Mullirit: EN 10204 / 3.1B

Përdorimi: Përdoret për shpërndarjen e lëngjeve me presion të ulët, të tilla si uji, gazi dhe vaji. Shpimet e naftës dhe prodhimi i makinerive, etj.

EFW pipe vs ERW pipe

Electric Fusion Welding (EFW steel pipe) refers to an electron beam welding, the use of high-speed movement of the electron beam directed impact kinetic energy is converted to heat the workpiece so that the workpiece leaving the melt, the formation of the weld.

It is mainly used for welding dissimilar steel welding sheet or which high power density, metal weldment can rapidly heated to high temperatures, which can melt any refractory metals and alloys. Deep penetration welding fast, heat-affected zone is extremely small, so small performance impact on the joints, the joint almost no distortion. But it has a requirement on a special welding room because welding using X-rays.

Electric Resistance Welding (ERW steel pipe): welding member combination is applying pressure through the electrodes, the use of current through the joint area of the contact surface and the adjacent heat generating resistance welding process method, Also known as contact welding. It has excellent toughness and dynamic load strength, welding deformation.

Commonly used spot welding, seam welding and butt three.

ERW pipe manufacturing process includes HFW. ERW have low, medium, high frequency welding processes, and HFW is specially for high-frequency electric resistance welding. The differences between ERW and HFW steel pipe, is EFW is a type of ERW process for ordinary and thin-wall thickness steel pipes.ERW pipe: Electric Resistance Welded Pipe

HFW pipe: High Frequency Welding pipe